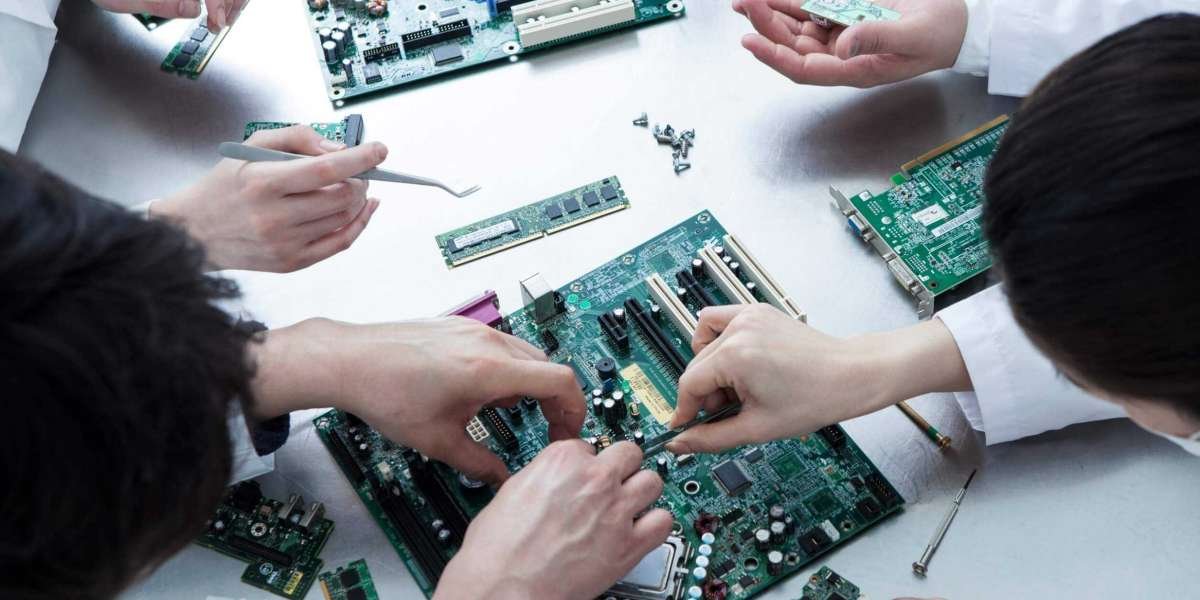

Printed circuit board (PCB) manufacturing includes the process of creating PCBs and the components that are used to make them. Let’s talk more about PCB assembly manufacturing and PCB assembly manufacturer.

A printed circuit board is an electronic component that provides a low-resistance path for electricity and helps to control the flow of electrons between different areas of an electronic circuit. The PCB also provides physical support for the electronic components, which may include resistors, capacitors and transistors.

Printed circuit boards are made from several layers of fiberglass or epoxy laminate, which are then coated with copper or other metal layers and filled with solder masks and other coatings. The finished boards are inspected for defects before being shipped out to customers who will use them in their products or sell them as replacement parts.

In most cases, a manufacturer will offer one or more standard sizes of printed circuit board — such as 4 x 6 inches or 8 x 12 inches — as well as custom sizes if needed by customers who want to integrate their own electronics into other devices. Most modern consumer electronics devices have at least one printed circuit board inside them somewhere, from smartphones and laptops to tablets and gaming systems.

Steps used by a PCB assembly manufacturer:

Printed circuit board manufacturing is a complex process. It involves many different steps that can be done at different locations. The following is an overview of the procedure:

Design: A designer creates the circuit diagram and makes sure it meets all requirements for the PCB.

PCB layout: A layout designer translates the design into copper layers, ensuring maximum performance from each layer.

Fabrication: Manufacturers use either photo or laser etching to produce the copper traces required by the design.

PTH drilling: PTH holes are drilled into components using chemical milling techniques or manual drilling machines.

Component placement: Components are placed onto the board and soldered in place, often using reflow soldering techniques where needed.

Finding a reliable PCB assembly manufacturer:

- Look for a high-quality PCB manufacturer:

It is important to find an experienced partner who can provide high-quality printed circuit boards (PCB). You need to ensure that your PCB designer is well versed in the demands of your industry, and will produce a circuit board that matches the quality you require.

- Find a manufacturer with good customer service:

A good PCB manufacturer will offer excellent customer service and be willing to answer any questions that you may have about their services. They should also be able to help you quickly, which can save you time and money in the long run.

- Make sure your manufacturer has lots of experience:

The more experience a PCB manufacturer has, the better their services are likely to be. If a company has been around for a long time, it is likely that they've amassed plenty of knowledge about the industry and how best to serve its customers.

- Pricing

This is important, but you should never sacrifice quality for the price. It is better to have a reliable PCB that meets your requirements than one that costs less.

The PCB manufacturer you choose will have a tremendous impact on the success of your project. They should be able to provide support, manufacturing expertise, and high-quality products consistently.