Electronic manufacturing services (EMS) are a supply chain management service that provides customized, complex electronic components and systems to customers and OEMs.

EMS services encompass a broad range of activities such as design, prototyping, engineering services, and testing.

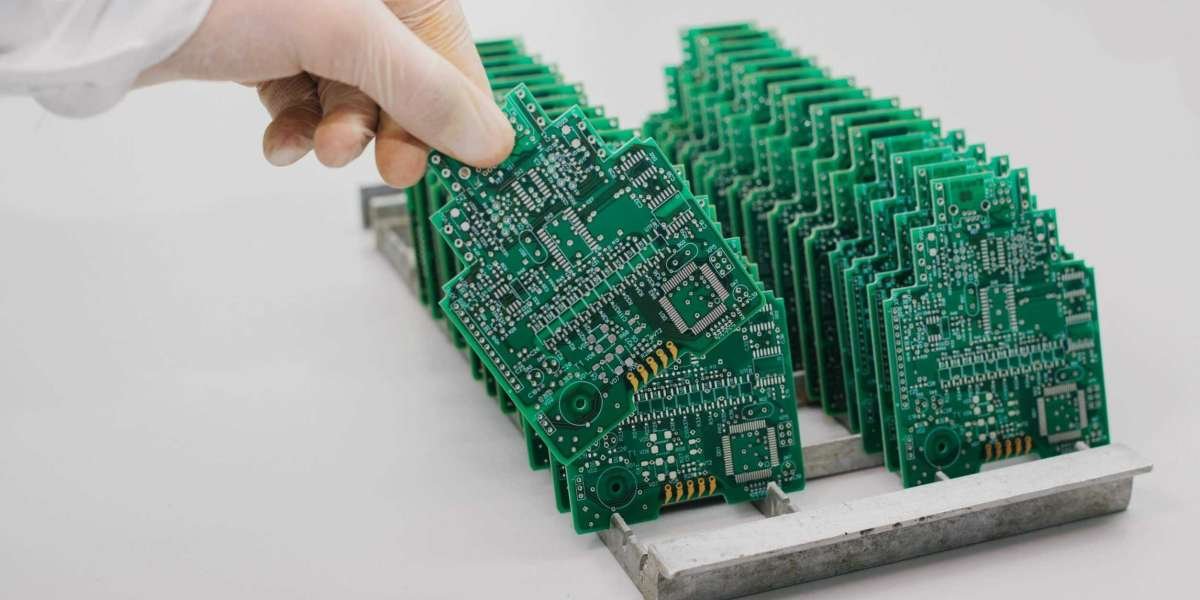

EMS providers offer their clients access to a wide range of technologies, including printed circuit board (PCB) fabrication, packaging design/fabrication, PCB assembly/test services, and final assembly.

EMS services are a group of manufacturing services that are performed at a distance from the end product. EMSs are typically performed on a contract basis by third-party service providers and involve the use of sophisticated computer-controlled machinery to produce electronic parts, devices, and systems. Services frequently provided by EMS include:

- Electronic assembly

- Electronic testing

- Electronic packaging

- Electronics repair

What are the benefits of hiring an electronic manufacturing services company?

EMS services are designed to help companies with the creation of electronic products. EMS companies provide a wide range of services, including service design, product design, production, and testing. The main objective of these companies is to reduce the time and cost involved in developing an electronic product while making sure that it meets the requirements of the customer.

The main benefit of using these services is that they allow you to focus on your core business while they take care of designing, building, and testing your new products or components. This means that you don’t have to invest in expensive equipment or hire highly skilled engineers who can help develop new products.

There are several types of EMS providers available today. Some offer only one service while others offer a broad range of services

Benefits

Here are some reasons why you should choose EMS services:

1) Cost savings

By outsourcing all aspects of production, you can save money by avoiding capital expenditures on expensive machinery and equipment while also eliminating overhead costs such as labor and rent on factory space.

2) Time-saving

If you have a lot of work to finish in your business, then time is a very important factor that you need to consider. This is why when hiring an EMS provider, they will take care of all the things that they can and do them as fast as possible without wasting any time or money on useless things that you would have done by yourself if hired directly by yourself.

3) Quality

When using an EMS provider, there will be no chance of low-quality products being produced especially if they are using machines that are very advanced in their fields like robots or CNC machines because these machines are designed specifically for this purpose only and hence no other machine could possibly match up with their standards because they have been built specifically for this purpose only.

4) Improved efficiency

With EMS, you can cut down on labor costs because most employees work with computers that have automated production processes. This allows them to work more productively without having to be touched by human hands.

5) Increased productivity

With electronic manufacturing services, you can increase your production output because there are fewer people involved in the manufacturing process.

Choosing the right EMS company

The choice is yours, but the best way to find the right company is to look for a company that has the best reputation in the area and has been in business for over 10 years. Another thing to consider is how much experience they have with your type of product.

If you are looking for a company that can help you design your product, then look for one that has expertise in 3D modeling and CAD software. This will ensure that your product is designed with quality and accuracy in mind.