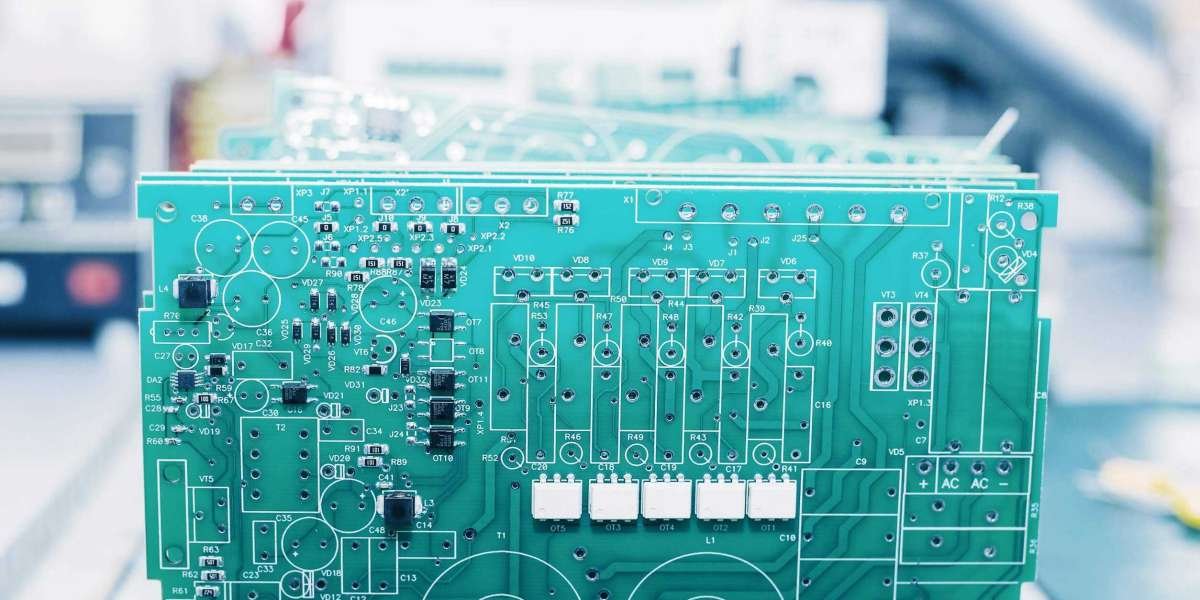

PCB assembly is the process of assembling a printed circuit board (PCB). Assembling involves mounting various electronic components onto the PCB to form a fully functional electronic product. PCB assembly services are getting more and more important in the electronics market, which makes it a very competitive one. With the rapid changes that occur in all parts of the world, companies have to adapt to all these changes to keep up with what their clients need, or else they will end up losing them to other companies.

Hiring a Reputed Company

There are many ways to get your printed circuit board assembly done. It could be that you have a small job and will do it yourself. Or, you may have a large job that requires the services of an expert company. Either way, there are some things that you should keep in mind when choosing a company that offers PCB assembly services.

You might want to choose a company that is close to where you live or work. This will make communication easier and quicker. You might also want to choose one that has been in business for a long time and has established relationships with other companies. This will help ensure that all of your needs are met and that you will not have any problems with getting the product from start to finish.

The key thing to remember is that the quality of your finished product depends on the quality of materials used in the manufacturing process. The best way to ensure high quality is by using high quality materials and having them assembled by experts who know what they're doing.

Surface Mount Technology

Surface Mount Technology (SMT) is a type of electronic assembly that uses components without leads. Traditionally, through hole components are used in most PCB assemblies. These parts have leads that protrude from the top of the board and they are soldered onto the PCB during assembly. SMT parts are integrated into plastic carriers that are then placed on the board using machines or by hand.

SMT assembly is cheaper than through hole technology and it can be faster because there is no need to solder each individual component. However, SMT requires special tools and more time for testing because the components cannot be easily removed once soldered down.

Through Hole Technology

Through-hole technology is a type of electronic component mounting in which the components are inserted from the top (solder side) of the board, and soldered to pads on the underside. PCBs (Printed Circuit Boards) are the main component of most electronic equipment. They consist of a board with various conductive traces or "traces" etched on it, which serve as connections between other components mounted on the PCB. The tracings may be formed by drilling holes through the board, or by printing onto a blank substrate.

Through-hole technology can also be used to mount surface-mount components directly onto a board or panel using special tooling. These hybrid assemblies may be referred to as Through-Hole Surface Mount Assembly (THSM).

Both Through-hole and SMT are the most popular techniques when it comes to high quality PCB assembly services.